About LIMEX

LIMEX Pellet is mainly made from calcium carbonate, and a small amount of resin such as polypropylene and polyethylene is added as a binder. It can be used for many types of plastic alternative products.

LIMEX Pellet provides many ecological and economical benefits, such as:

- Can be processed with existing equipment and general blades - no special tools needed

- Can be provided at a stable price compared to petroleum-based resin, since limestone is abundant in nature

- Greenhouse gas emissions can be reduced over the entire product life cycle

- Patented in over 40 countries and registered in STePP (Sustainable Technology Presentation Platform) by UNIDO

- Almost no water is used in the manufacturing process; no forest resources are used

- Can also be used as an alternative to filler master batch that can grant a higher filling rate of calcium carbonate, resulting in cost reduction and excellent quality - ideal for blown film molding such as food packaging, shopping bags and waste bags *cannot be used when the product contains less than 50% inorganic filler

Plastic Alternative Benefits

Reduces amount of petroleum-derived

plastic used

Reduces GHG emissions, including CO2, by 41%

Paper Alternative Benefits

Reduces water

consumption by 97%

Manufactured with 100% renewable energy and zero CO2 emissions

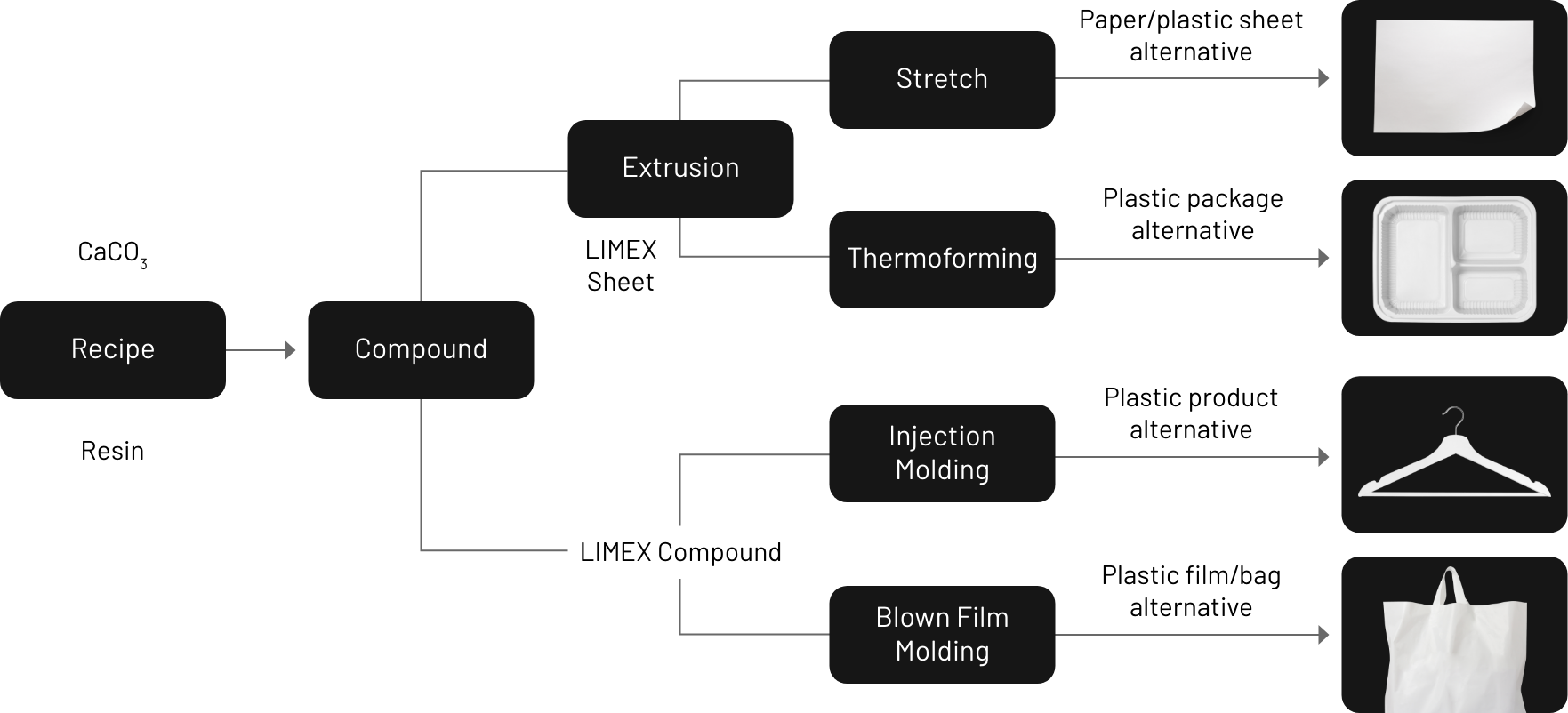

Molding

Methods

LIMEX can be processed with existing plastic molding machinery.

LIMEX brand can only be used when the product contains more than 50% calcium carbonate.

Learn More

Applications

Thermoforming

- Food Containers

- Cups

Span Bond Molding

- Non-Woven (Fabric)

Blow Molding

- Bottles

- Tubes

Injection Molding

- Stationery

- Hotel Amenities

- Industrial Goods

Blown Film Molding

- Shopping Bags

- Packaging Film

Extrusion Molding

- Building Materials

- Sheet

- Film

- Illuminated Posters/Billboards

Here are some examples of how LIMEX has been used for over 8,000 companies in Japan:

Stationery Backlit signage

- Trash bags

- Shopping bags

- Drinking cups

- Construction material

- Plastic Alternative Applications

Paper Alternative Applications

- Booklets

- Reports

- Menus

- IR reports

- POP

LIMEX Pellet List

| Grade | Country of Manufacture | Application | Resin Type | Remarks |

|---|---|---|---|---|

| PE78-02M | Vietnam | Blown Film Molding | Non-bio | |

| PE78-02BM | Vietnam | Blown Film Molding | Bio | |

| PP60-18L | Vietnam | Injection Molding | Non-bio | MFR Low |

| PP60-19M | Vietnam | Injection Molding | Non-bio | MFR Mid |

| PP60-201H | Vietnam | Injection Molding | Non-bio | MFR High |

| PP80-24L | Vietnam | Extrusion/Thermoforming | Non-bio | |

| PP80-25L | Japan | Extrusion/Thermoforming | Non-bio |

LIMEX Sheet List

| White - Soft | Translucent - Hard | White - Hard | |||||||||

| Item | Standard | 80μm | 150μm | 200μm | 300μm | 400μm | 150μm | 200μm | 300μm | 400μm | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | μm | JIS K7130 | 80 | 150 | 200 | 300 | 400 | 150 | 200 | 300 | 400 |

| Basis Weight | g/m2 | JIS P8124 | 85 | 153 | 199 | 341 | 380 | 220 | 303 | 450 | 600 |

| Density | kg/m3 | JIS K7112 | 1,060 | 985 | 958 | 1,114 | 919 | 1,470 | 1,467 | 1,464 | 1,467 |

| Whiteness | % | JIS P8148 | 96 | 94 | 95 | 94 | 96 | 76 | 76 | 91 | 92 |

| Opacity | % | JIS P8149 | 85 | 93 | 96 | 97 | 99 | 64 | 70 | 95 | 97 |

| Tensile strength (MD) | MPa | JIS K7127 | 27 | 32 | 29 | 22 | 24 | 22 | 21 | 19 | 18 |

| Tensile strength (TD) | MPa | JIS K7127 | 30 | 9 | 9 | 11 | 9 | 15 | 15 | 15 | 15 |

| Surface resistivity | Ω | JIS K6911 | 4E+11 | 1 ×1012 | 1 ×1012 | 1 ×1012 | 7 ×1011 | 7 ×1012 | 7 ×1012 | 3 ×1012 | 4 ×1012 |

| Volume resistivity | Ω cm | JIS K6911 | 5E+15 | 2 ×1012 | 2 ×1012 | 4 ×1011 | 2 ×1014 | 3 ×1010 | 3 ×1010 | 3 ×1010 | 3 ×1010 |